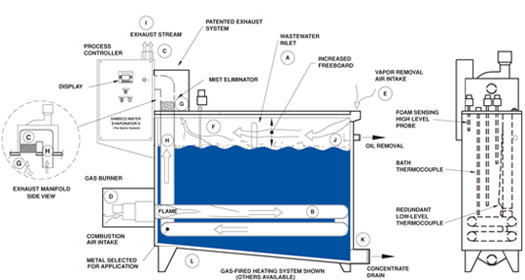

Samsco Water Evaporator II Principles of Operation

- Wastewater is fed to tank as required at (A).

- Blower (C) draws air stream into tank at (E) to remove vapors. Blower also draws combustion air into burner at (D). Heat exchanger (B) contains combustion gas, preventing its release into tank.

- Heat exchanger causes water to boil. Air moving over boiling surface (F) captures water vapor.

- Moisture-saturated air leaves tank through coalescing mist eliminator where oil/water droplets are removed and clean steam passes into manifold at (G).

- Flue gas (H) joins water vapor at blower manifold entrance—not exhausted into tank.

- Air streams—environmentally approved—are mixed in blower and exhausted through stack to atmosphere (I).

- When boiling is interrupted, oils—freed from emulsion—float to surface and are decanted at trough (J) automatically, or manually.

- Solids settle to tank’s sloping trough floor (L) and are removed with concentrated liquid through large clean-out port (K).

Contact: Sales at 603-668-7111, sales@samsco.com ~ Service at 603-668-7111 ext 7111 or 216-400-8207, service@samsco.com

Home | About Us | Products | Services | Information & Resources | Contact Us

Samsco Water Evaporator II |

WasteSaver (Vacuum Distillation) |

Envirostill MVR |

Water Treatment Technologies |

Poly Atmospheric Evaporators |

Auxiliary Equipment

© Copyright

SAMSCO. All rights reserved. A Senney Enterprises Company:

Met-Chem, STD Specialty Filters, Lamports Filter Media, Murray Fabrics, Poly Products, Auto Technology, Samsco, Lakeside Water Treatment, Micropure Filtration, Jaxon Filtration, American Ecotech, Custom Instrumentation Services Corp., Ambilabs, AQ Matic.